1. Introdución

This manual provides essential information for the safe and efficient installation, operation, and maintenance of your AB BL26C-10D Brazed Plate Heat Exchanger. This unit is designed for efficient heat transfer in various water-to-water applications.

The BL26C-10D model features 10 brazed plates, measuring 5 inches by 12 inches, with 1 1/4 inch MPT connections. It is constructed from high-quality 316L stainless steel, brazed with 99.9% copper, ensuring durability, resistance to leakage, and the ability to withstand high pressure and temperature.

2. Especificacións do produto

| Especificación | Detalle |

|---|---|

| Fabricante | AB |

| Número de modelo | BL26C-10D |

| Número de peza | BL26C-10D |

| Peso do elemento | 7.39 libras |

| Dimensións do produto | 12 x 5 x 1.25 polgadas |

| Número de placas | 10 |

| Material | 99.9% Copper, Stainless Steel 316L |

| Tipo de conexión | 1 1/4" MPT (Male Pipe Thread) |

| Máx. Presión de operación | 435 PSI |

| Máx. Temperatura de funcionamento | 482 °F |

| Capacidade BTU | 110,000 - 280,000 BTU/hr (application dependent) |

3. Aplicacións

The AB BL26C-10D Brazed Plate Heat Exchanger is versatile and suitable for a wide range of heat transfer applications, including but not limited to:

- Domestic Water Heating

- Sistemas de calefacción por piso

- Sistemas de fusión de neve

- District or Zone Heating Systems

- Outdoor Wood Furnaces

- Hydraulic and Lube Oil Coolers

- Radiator Heating

- Calefacción hidrónica

- Solar Heating Systems

- Wood Boiler Systems

- Homebrew Chillers

- HVAC Heating & Cooling

4. Configuración e instalación

Proper installation is crucial for the optimal performance and longevity of your heat exchanger. Due to the specialized nature of hydronic systems, professional installation by a qualified technician is highly recommended.

4.1. Connection Points

The heat exchanger features 1 1/4 inch MPT (Male Pipe Thread) connections. Ensure all connections are properly sealed to prevent leaks. The smooth thread design facilitates an easy and flexible hookup.

4.2. Dirección do fluxo

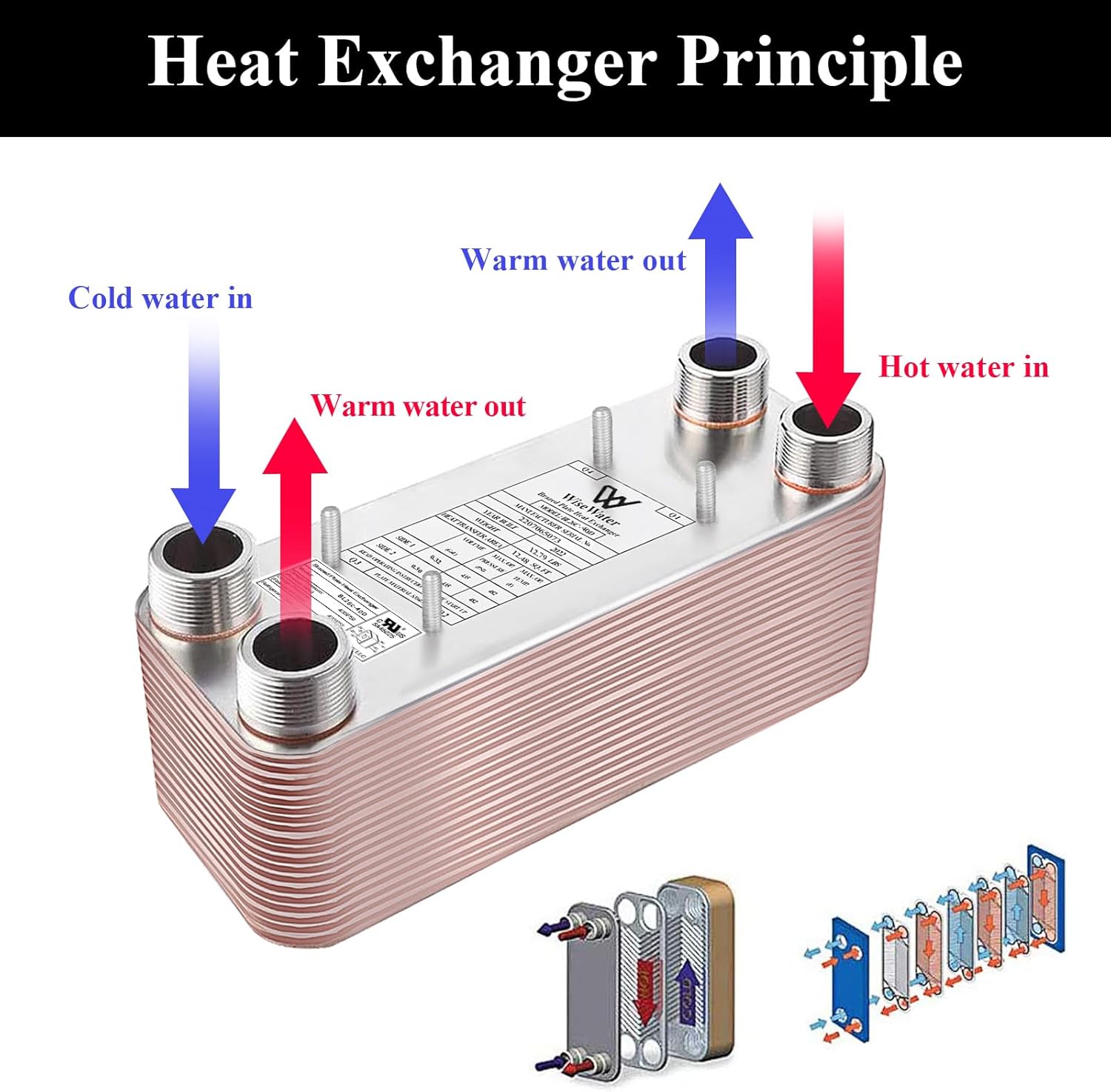

For optimal heat transfer, fluids should typically flow in a counter-current direction. Consult the port labels (Q1, Q2, Q3, Q4) on the unit and your system design for correct fluid routing.

4.3. System Sizing

Refer to the Hydronic Duty Tables provided by the manufacturer for appropriate sizing based on your specific application (e.g., domestic hot water, floor heating, snow melting) and desired BTU output. These tables provide guidance on boiler flow, system flow, and kBtuh/hr for various models.

5. Principios de funcionamento

The brazed plate heat exchanger facilitates efficient heat transfer between two fluids without direct mixing. Hot fluid enters one set of channels, and cold fluid enters an alternating set of channels. Heat is transferred across the thin, corrugated stainless steel plates.

5.1. Heat Exchange Mechanism

The unit utilizes an asymmetric fish bone plate design. This design creates strong turbulences within the fluid flow, which significantly enhances the heat transfer performance and efficiency. A heat recovery rate of over 90% can be achieved.

6. Mantemento

Brazed plate heat exchangers are generally low-maintenance devices due to their robust construction and sealed design. However, periodic checks are recommended to ensure continued optimal performance.

- Inspección visual: Regularly inspect the exterior of the unit for any signs of external leakage, corrosion, or physical damage.

- Monitorización de presión: Monitor system pressures to ensure they remain within the specified operating limits (Max. 435 PSI).

- Monitorización de temperatura: Verify that operating temperatures do not exceed the maximum specified temperature (Max. 482°F).

- Calidade do fluído: Maintain good fluid quality in both circuits to prevent fouling or scaling, which can reduce efficiency over time.

- Limpeza: If a significant drop in performance is observed, chemical cleaning may be necessary. Consult a professional for appropriate cleaning procedures to avoid damaging the unit.

7 Solución de problemas

This section provides general guidance for common issues. For complex problems, contact a qualified technician.

| Problema | Causa posible | Solución |

|---|---|---|

| Reduced Heat Transfer Efficiency |

|

|

| External Leaks |

|

|

| Ruídos pouco comúns |

|

|

8. Garantía e soporte

Your AB BL26C-10D Brazed Plate Heat Exchanger comes with a 1 ano de garantía covering manufacturer defects. We are committed to providing 100% satisfaction service and premium quality products.

If you encounter any issues or have questions regarding your product, please contact the seller or manufacturer directly for assistance. Ensure you have your model number (BL26C-10D) and purchase details available when contacting support.