1. Produto rematadoview

The Chicago Pneumatic CP7406 is a heavy-duty 1/4-inch (6 mm) air angle die grinder designed for professional use in various metal fabrication, vehicle servicing, and repair applications. It features a powerful 0.34 HP (250 W) motor capable of 23,000 RPM, providing efficient grinding and polishing performance.

As características principais inclúen:

- Poderoso e rápido: 0.34 horsepower motor delivers a maximum speed of 23,000 RPM for heavy-duty tasks.

- Deseño ergonómico: Compact and lightweight with a thermoplastic rubber (TPR) handle for superior grip and a composite casing to reduce heat transfer, ensuring operator comfort.

- Seguridade mellorada: Equipped with a lock-off throttle to prevent accidental start-ups and a robust aluminum alloy body for durability.

- Aplicacións versátiles: Ideal for welding, woodworking, automotive detailing, stainless steel polishing, deburring, and chamfering.

- Innovative Spindle Lock System: Allows for quick and easy burr changes with only one spanner wrench, improving productivity.

Figura 1: global view of the Chicago Pneumatic CP7406 Air Angle Die Grinder.

2. Información de seguridade

Always read and understand all safety warnings and instructions before operating the tool. Failure to follow these warnings and instructions may result in electric shock, fire, and/or serious injury.

- Usar equipos de protección individual (EPI) axeitados, incluíndo protección ocular, protección auditiva e luvas.

- Asegúrese de que a peza de traballo estea firmemente clampantes de comezar calquera operación.

- Disconnect the air supply before changing accessories, performing maintenance, or when the tool is not in use.

- Non utilice a ferramenta en atmosferas explosivas, como en presenza de líquidos, gases ou po inflamables.

- Manteña os nenos e os espectadores afastados mentres manexa unha ferramenta eléctrica.

- Manteña unha suxeición firme da ferramenta durante o funcionamento.

- Use only accessories rated for the tool's maximum RPM.

3. Configuración

Before initial use, ensure your air compressor can provide a stable air pressure of 90 PSI (6.2 bar) and sufficient airflow for optimal performance.

3.1 Conexión á subministración de aire

- Ensure the tool's throttle is in the OFF position.

- Apply a few drops of pneumatic tool oil into the air inlet.

- Connect a suitable air hose (minimum 1/4-inch inner diameter) to the tool's air inlet.

- Connect the other end of the air hose to your regulated air supply.

3.2 Changing Carbide Burrs

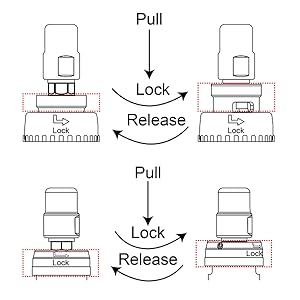

The CP7406 features an innovative spindle lock system for quick and easy burr changes, requiring only one spanner wrench.

Imaxe 2: Primeiro plano view of the spindle lock mechanism.

- Desconecte a ferramenta da subministración de aire.

- Push and rotate the spindle lock mechanism until it engages, securing the collet.

- Use a chave inglesa fornecida para afrouxar a porca da pinza.

- Remove the old burr and insert the new burr into the collet, ensuring it is fully seated.

- Tighten the collet nut firmly with the spanner wrench.

- Disengage the spindle lock by rotating it back to its original position.

Figure 3: Visual guide for changing carbide burrs with the spindle lock system.

4. Instrucións de funcionamento

The CP7406 is designed for precision and power in various applications. Always ensure proper ventilation and safety precautions are in place.

4.1 Funcionamento xeral

- Conecte a ferramenta á fonte de aire.

- Hold the tool firmly with both hands, if possible, or ensure a secure grip.

- Depress the lock-off throttle to start the tool.

- Apply the rotating burr to the workpiece with steady, controlled pressure. Avoid excessive force, which can damage the burr or the tool.

- Move the tool smoothly across the surface to achieve desired results.

- Release the throttle to stop the tool.

4.2 Aplicacións

The CP7406 is suitable for a range of tasks:

- Moenda: Removing material from surfaces.

- Desbarbado: Smoothing rough edges after cutting or machining.

- Achaflanado: Creating a beveled edge.

- Pulido: Achieving a smooth, finished surface.

- Matching Welded Surfaces: Blending welds for a seamless finish.

Figure 4: Common applications for the CP7406 die grinder.

4.3 Ergonomía e confort

The tool's thermoplastic rubber (TPR) handle provides a secure grip, preventing slippage. Its rugged composite casing acts as an insulator, reducing heat transfer from the motor to the sleeve, allowing for comfortable extended use.

Figure 5: Ergonomic features for enhanced user comfort.

5. Mantemento

Regular maintenance ensures the longevity and optimal performance of your CP7406 die grinder.

- Lubricación diaria: Apply a few drops of high-quality pneumatic tool oil into the air inlet before and after each use, or every few hours of continuous operation.

- Filtro de ar: Ensure your air supply system has a clean and properly functioning air filter to prevent contaminants from entering the tool.

- Limpeza: Keep the tool clean and free from debris. Wipe down the exterior with a clean cloth. Do not use harsh solvents.

- Inspección da pinza: Regularly inspect the collet and collet nut for wear or damage. Replace if necessary to ensure proper burr retention.

- Inspección da mangueira: Check air hoses for cuts, abrasions, or leaks. Replace damaged hoses immediately.

6 Solución de problemas

If you encounter issues with your CP7406 die grinder, refer to the following common problems and solutions:

| Problema | Causa posible | Solución |

|---|---|---|

| Tool does not start or runs slowly | Low air pressure; Insufficient air flow; Lack of lubrication; Worn motor parts | Check air supply and regulator setting; Use larger diameter hose; Lubricate tool; Contact service center |

| Vibración excesiva | Bent or damaged burr; Worn collet; Internal wear | Replace burr; Replace collet; Contact service center |

| Fugas de aire | Loose fittings; Damaged O-rings or seals | Tighten connections; Replace damaged components |

| A ferramenta quéntase | Overuse; Lack of lubrication; Internal friction | Allow tool to cool; Lubricate tool; Contact service center |

For issues not listed above or if solutions do not resolve the problem, please contact Chicago Pneumatic customer support.

7. Especificacións

Detailed technical specifications for the Chicago Pneumatic CP7406 Air Angle Die Grinder:

Figure 6: Specifications for the CP74 series, including CP7406.

| Especificación | Valor |

|---|---|

| Número de modelo | CP7406 |

| Número de peza | 8941074060 |

| Tamaño de pinza | 1/4 de polgada (6 mm) |

| Poder | 0.34 HP / 250 W |

| Maximum Rotational Speed (Free Speed) | 23,000 RPM |

| Peso do elemento | 1.32 libras (0.60 kg) |

| Dimensións do produto (L x W x H) | 6.42 x 1.5 x 3.62 polgadas |

| Air Pressure Requirement | 90 PSI (6.2 bar) |

| Nivel de son | 78.1 dB |

| Material | Metal |

| UPC | 015451781514 |

| País de Orixe | Taiwán |

8. Garantía e soporte

The Chicago Pneumatic CP7406 Air Angle Die Grinder comes with a 1 ano de garantía limitadaConserva o comprobante de compra para reclamacións de garantía.

For technical assistance, warranty service, or to find authorized service centers, please visit the official Chicago Pneumatic websitio web ou póñase en contacto co seu servizo de atención ao cliente. Tamén pode visitar o Chicago Pneumatic Store on Amazon para obter máis información sobre o produto e recursos.